Digital Twins for Monitoring, Optimization and Risk Management for the Steel, Cement and Metal Refining Industries

Management of material resource interdependencies is becoming increasingly complex because of accelerating weather volatility

Requiring breakthrough innovations across three key themes

-

Hyper-productivity in use of energy and materials

Digital Twins for system-wide energy and material optimization in steel, cement, mining and metal refining industries

-

Material industry supply chains that are resilient to extremes

Digital Twins for material industry supply chain optimization and operational risk management

-

Deep decarbonization of hard to abate material industries

Digital Twins for deep decarbonization of steel, cement, mining and metal refining industries

We develop and operate Digital Twins for Monitoring, Optimization and Risk Management

Leveraging breakthroughs in novel sensing, artificial intelligence, and autonomous systems & robotics.

Digital Twins for Monitoring, Optimization and Risk Management

As foundations for Industry 4.0 and Supply Chain 4.0 platforms and solutions

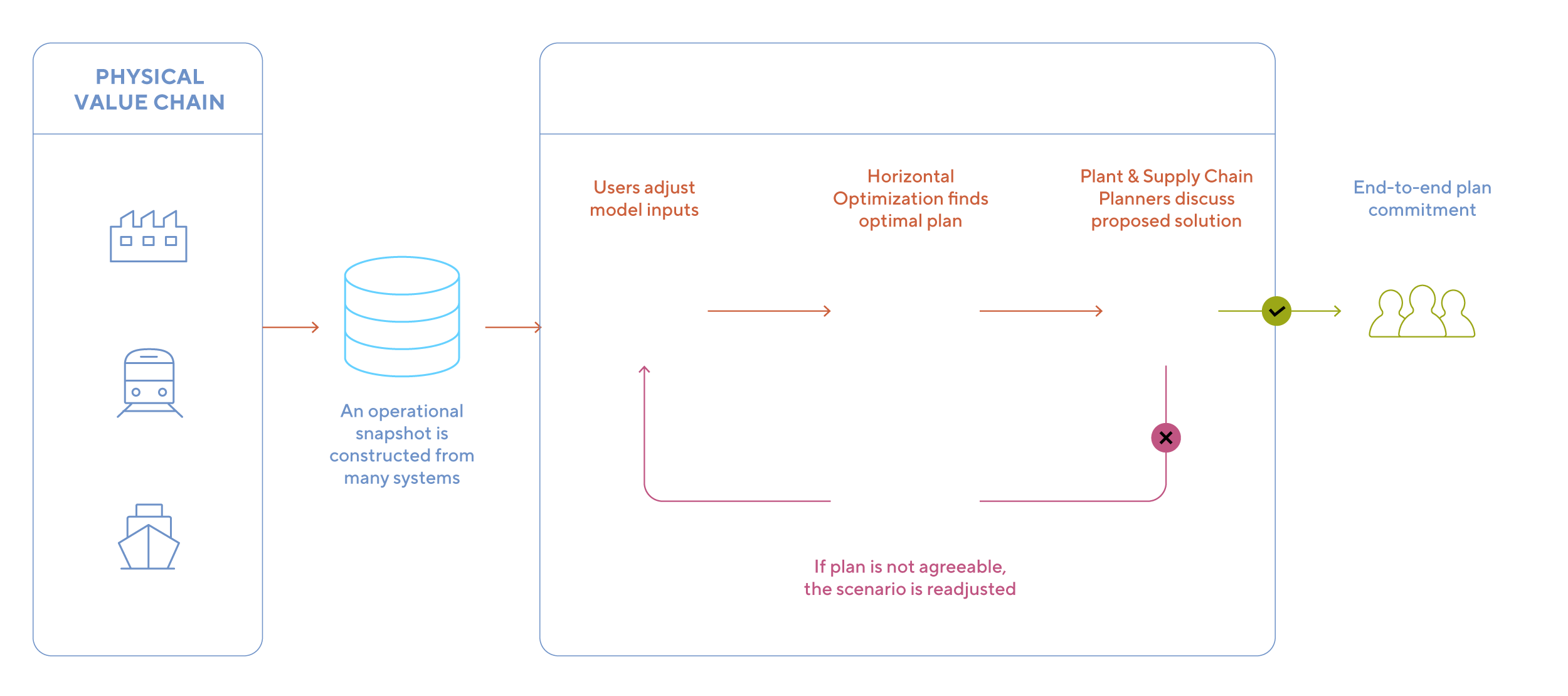

REAL TIME MONITORING ALLOW PLANNERS & OPERATORS TO ANALYZE DIFFERENT ‘WHAT IF’ SCENARIOS

END TO END OPTIMIZATION FINDS OPTIMAL PLANS FOR CURRENT PLANT OPERATIONAL SETUPS

SUPPLY CHAIN RISK MANAGEMENT PLATFORMS AUTOMATE ANOMALY DETECTION ACROSS MATERIAL SUPPLY CHAINS

BEFORE: SILOED AND FRAGMENTED APPROACH TO ANOMALY DETECTION

AFTER: END TO END CONTEXTUAL INTELLIGENCE AND ANOMALY ALERTING

A SpaceTime Labs venture with deep domain expertise in Digital Twins integrating novel sensing, artificial intelligence, and autonomous robotic systems for the material industries.